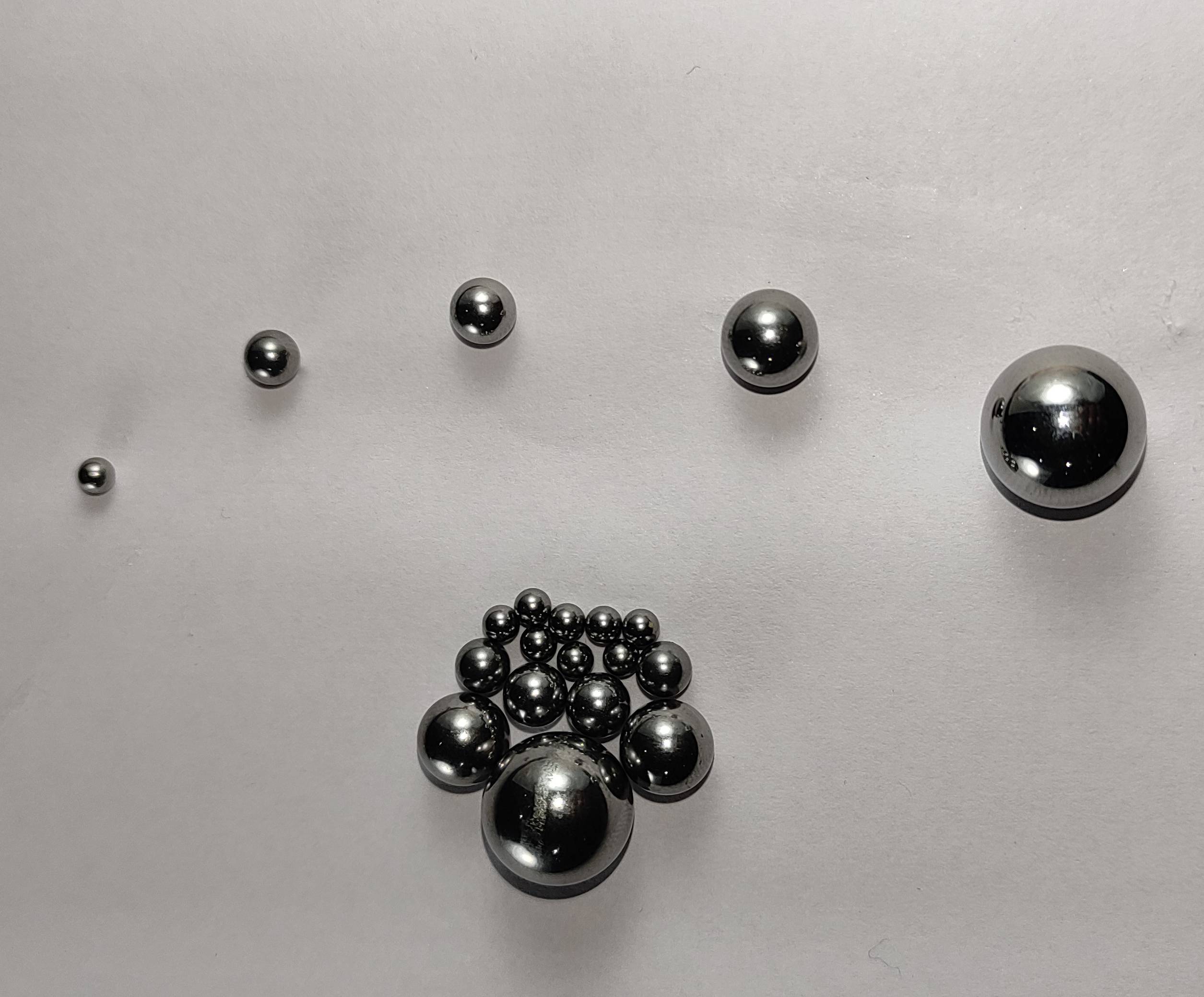

Mild Steel Ball

Mild steel balls are spherical objects made from mild steel, a low-carbon steel alloy known for its malleability, ductility, and versatility. Mild steel balls have a wide range of applications, including in bearings, automotive components, and industrial equipment. While I don’t have specific information about DSP Precision Products Pvt Ltd’s processes, I can provide a general overview of the manufacturing process for mild steel balls:

Mild Steel Ball Manufacturing Process:

- Raw Materials: The primary raw material for manufacturing mild steel balls is low-carbon steel wire or rod. Mild steel contains a relatively low percentage of carbon, typically less than 0.3%.

- Wire Drawing: The mild steel wire is drawn through a series of dies to reduce its diameter to the desired size. This process also helps improve the wire’s surface finish and consistency.

- Cutting: The drawn wire is cut into shorter lengths, which will be used to form individual mild steel balls.

- Cold Heading: The cut wire segments are cold headed to create a spherical shape. Cold heading is a process in which the wire is placed in a die and subjected to high pressure to form it into a ball shape.

- Annealing: After shaping, the mild steel balls may undergo an annealing process to relieve any internal stresses induced during cold heading and to improve their mechanical properties. Annealing involves heating the balls to a specific temperature and then cooling them slowly.

- Heat Treatment (Optional): Depending on the desired properties and hardness of the mild steel balls, they may undergo heat treatment processes, such as quenching and tempering, to achieve the desired mechanical characteristics.

- Grinding and Polishing: To achieve precise dimensions and a smooth surface finish, the mild steel balls are subjected to grinding and polishing processes. These processes are crucial for achieving tight tolerances and a high-quality surface finish.

- Quality Control: Throughout the manufacturing process, stringent quality control measures are implemented to ensure that the mild steel balls meet the specified standards. This includes dimensional checks, hardness testing, surface quality inspections, and chemical composition analysis.

- Packaging and Shipping: Once the mild steel balls pass quality control, they are packaged according to customer requirements and prepared for shipment.

DSP Precision Products Pvt Ltd, as a manufacturer, would have its own proprietary processes and quality control procedures to meet the specific requirements of its customers.

If you are interested in purchasing mild steel balls from DSP Precision Products Pvt Ltd or have specific size requirements, you should contact the company directly to inquire about their manufacturing capabilities, product offerings, and any specific requirements you may have. The address you provided can be used to reach out to them.