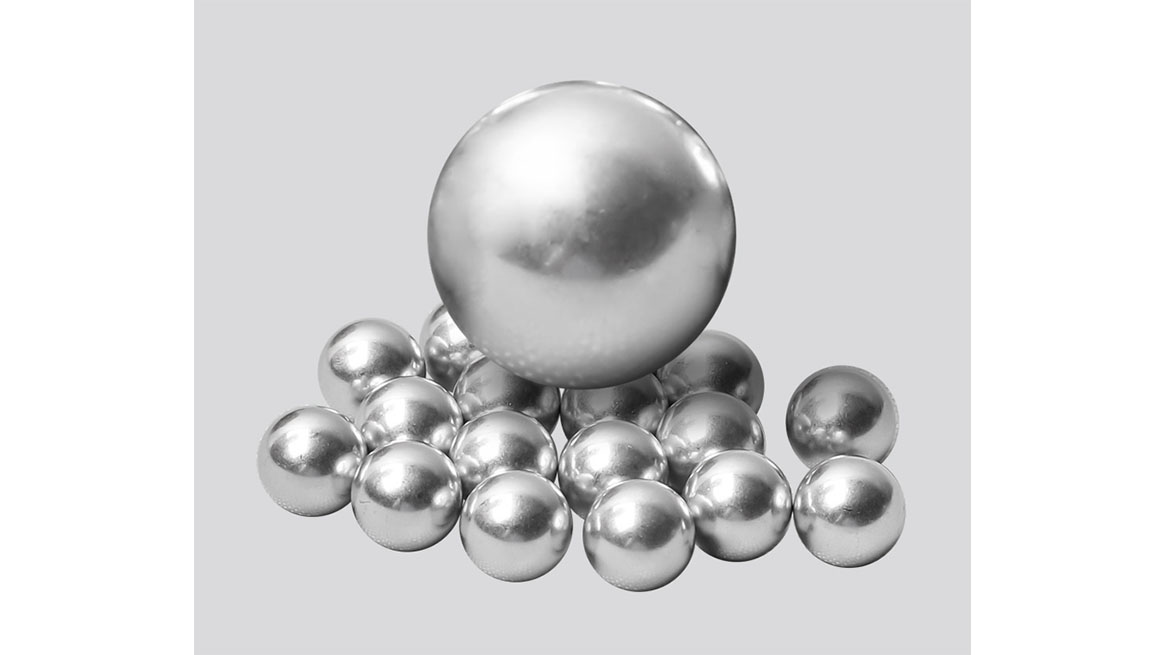

Aluminium Ball

Aluminum balls are spherical objects made from aluminum, a lightweight and corrosion-resistant metal known for its versatility and use in various applications, including aerospace, automotive, and consumer goods. These balls can serve as components in bearings, valves, and other precision machinery. While I don’t have specific information about DSP Precision Products Pvt Ltd, I can provide a general overview of the manufacturing process for aluminum balls:

Aluminum Ball Manufacturing Process:

- Raw Materials: The primary raw material for manufacturing aluminum balls is high-quality aluminum alloy. The choice of alloy depends on the desired properties of the final product, including strength, corrosion resistance, and conductivity.

- Melting: The selected aluminum alloy is melted in a furnace to form a molten liquid.

- Casting: The molten aluminum is poured into spherical molds, which can be made of various materials, including steel or cast iron. These molds have cavities in the shape of spheres, and as the molten aluminum cools and solidifies, it takes on the spherical shape.

- Cooling and Solidification: The molten aluminum in the molds cools and solidifies, forming spherical balls.

- Trimming and Finishing: After solidification, the aluminum balls may undergo trimming and finishing processes to remove any excess material and achieve the desired size and shape. This step is crucial for maintaining dimensional accuracy.

- Heat Treatment (Optional): Depending on the aluminum alloy and the desired properties, the balls may undergo heat treatment processes to achieve the desired hardness and mechanical characteristics.

- Surface Treatment (Optional): Depending on the application and customer requirements, the aluminum balls may undergo surface treatments like anodizing or coating to enhance their performance or appearance.

- Quality Control: Throughout the manufacturing process, stringent quality control measures are implemented to ensure that the aluminum balls meet the specified standards. This includes dimensional checks, surface quality inspections, and chemical composition analysis.

- Packaging and Shipping: Once the aluminum balls pass quality control, they are packaged according to customer requirements and prepared for shipment.

Please note that the specific manufacturing process may vary depending on factors such as the alloy used, size of the balls, and intended application. DSP Precision Products Pvt Ltd, as a manufacturer, would have its own proprietary processes and quality control procedures to meet the specific requirements of its customers.

If you are interested in purchasing aluminum balls from DSP Precision Products Pvt Ltd, you should contact the company directly to inquire about their manufacturing capabilities, product offerings, and any specific requirements you may have. The address you provided can be used to reach out to them.