Steel Balls

A Complete Guide to Steel Balls

Introduction

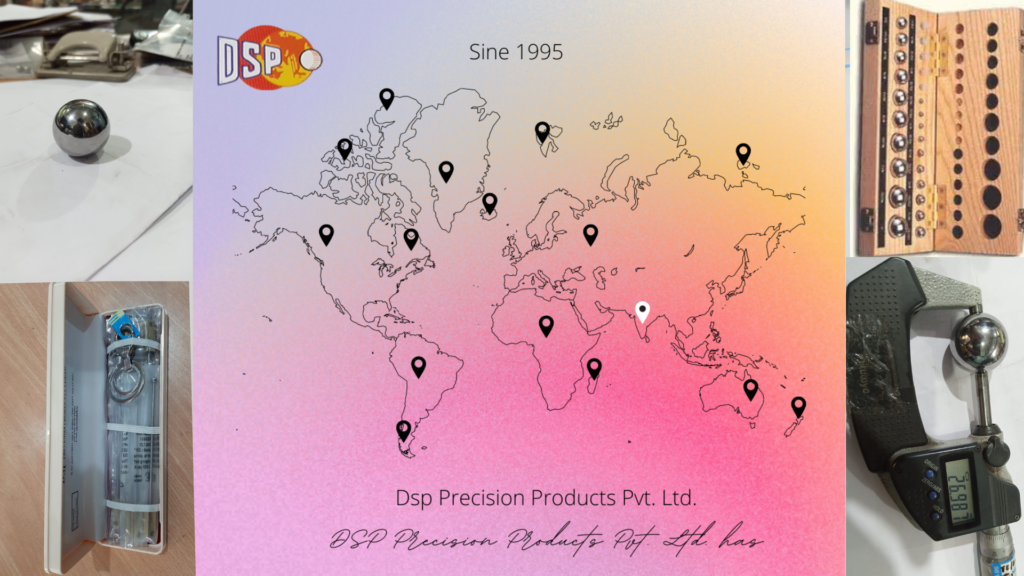

Steel balls are a cornerstone of modern engineering, pivotal in the functioning of countless machines and devices across various industries. Their applications are as diverse as their manufacturing processes are intricate. At the forefront of this industry is DSP Precision Products Pvt. Ltd., a distinguished manufacturer based in Baddi, Himachal Pradesh. With over 30 years of experience, DSP Precision Products has become synonymous with precision and reliability in the realm of steel ball production. This comprehensive blog explores the intricacies of steel ball manufacturing, the diverse applications of these products, and the global influence of DSP Precision Products.

1. Understanding Steel Balls

Steel balls are small, spherical components used in a range of mechanical systems. They are valued for their precision, durability, and resistance to wear and tear. These attributes make them indispensable in numerous applications. Steel balls are typically made from various grades of steel, including carbon steel, chrome steel, stainless steel, and alloy steel. Each type of steel ball offers unique properties tailored to specific uses.

2. The Manufacturing Excellence of DSP Precision Products Pvt. Ltd.

2.1 History and Legacy

Established over three decades ago, DSP Precision Products Pvt. Ltd. has built a formidable reputation in the steel ball manufacturing industry. Located in Baddi, Himachal Pradesh, their state-of-the-art facility is equipped with advanced machinery and technology, ensuring that every steel ball meets the highest standards of precision and quality.

2.2 The Manufacturing Process

The production of steel balls at DSP Precision Products involves several critical stages:

- Material Selection: The quality of steel used is fundamental. DSP Precision Products selects premium-grade steel, ensuring that the balls exhibit the desired properties such as hardness, durability, and corrosion resistance.

- Heat Treatment: Heat treatment is crucial for enhancing the mechanical properties of steel balls. This process involves heating the balls to a specific temperature and then cooling them rapidly to achieve the desired hardness and strength.

- Grinding and Sizing: After heat treatment, the balls are ground to achieve precise dimensions and a smooth surface. This step is vital for ensuring that the balls meet strict tolerances and performance requirements.

- Inspection and Quality Control: Rigorous inspection procedures are employed to guarantee the quality of the steel balls. This includes checking for dimensional accuracy, surface finish, and hardness.

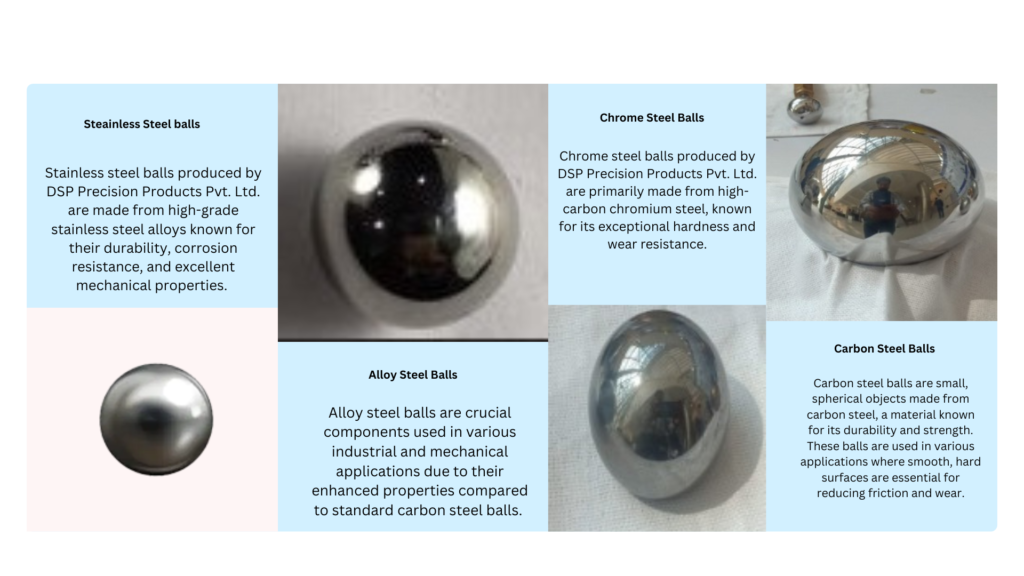

2.3 Types of Steel Balls

DSP Precision Products manufactures a wide range of steel balls, each designed to meet specific industrial needs:

- Chrome Steel Balls: Known for their high hardness and wear resistance, chrome steel balls are commonly used in bearing applications. They are ideal for situations where high load-bearing capacity and durability are required.

- Stainless Steel Balls: These balls offer excellent resistance to corrosion and are used in environments where exposure to moisture or chemicals is common. They are often found in applications such as food processing and medical devices.

- Carbon Steel Balls: Carbon steel balls are known for their hardness and are used in applications where high stress and impact resistance are necessary. They are commonly employed in grinding and milling operations.

- Alloy Steel Balls: Designed to withstand high stress, alloy steel balls are used in heavy-duty applications. They are often found in mining equipment and other high-load machinery.

3. Diverse Applications of Steel Balls

Steel balls are integral to a wide array of industries and applications. Their versatility and functionality make them suitable for numerous uses:

3.1 Automotive Industry

In the automotive industry, steel balls are essential components in various systems:

- Bearings: Steel balls are crucial in ball bearings, which reduce friction and facilitate smooth rotation of automotive parts such as wheels and transmissions.

- Transmission Systems: They are used in gear mechanisms to ensure smooth and reliable power transfer.

- Steering Mechanisms: Steel balls are employed in steering systems to provide precise control and stability.

3.2 Aerospace Industry

The aerospace sector relies on steel balls for their performance in high-stress environments:

- Aircraft Bearings: Steel balls are used in aircraft bearings to handle the extreme conditions of flight and ensure reliable operation.

- Control Systems: They play a role in the precision control systems of aircraft, including flight control and navigation systems.

3.3 Industrial Machinery

Steel balls are integral to the functioning of various industrial machines:

- Pumps: They are used in pumps to reduce friction and enhance efficiency in fluid transfer.

- Valves: Steel balls are employed in ball valves to regulate the flow of fluids and gases.

- Conveyors: In conveyor systems, steel balls facilitate smooth and efficient material handling.

3.4 Consumer Goods

Steel balls are also found in everyday products:

- Ballpoint Pens: The smooth writing experience of ballpoint pens is made possible by the steel balls used in their mechanisms.

- Skateboards: Steel balls are used in skateboard bearings to ensure smooth and stable rides.

4. DSP Precision Products’ Global Reach

4.1 Import and Export Operations

DSP Precision Products Pvt. Ltd. has established a robust global presence through its import and export operations. Their high-quality steel balls are distributed to clients across the world, reflecting their commitment to excellence and customer satisfaction.

4.2 International Partnerships

The company has formed strategic partnerships with international clients and distributors, ensuring that their products are available in diverse markets. Their global network facilitates timely delivery and consistent quality for customers around the world.

5. Commitment to Quality and Innovation

5.1 Quality Assurance

DSP Precision Products is dedicated to maintaining the highest quality standards. Their comprehensive quality assurance processes include:

- Certifications: The company holds various industry certifications that validate its adherence to international quality standards.

- Continuous Improvement: They invest in research and development to enhance their products and manufacturing processes.

- Customer Feedback: DSP Precision Products actively seeks feedback from clients to ensure their products meet and exceed expectations.

5.2 Future Innovations

As technology evolves, DSP Precision Products is committed to exploring new materials and manufacturing techniques. Their focus on sustainability and efficiency reflects their dedication to leading the industry into the future.

6. Case Studies and Success Stories

6.1 Automotive Success

A leading automotive manufacturer benefited from DSP Precision Products’ high-quality chrome steel balls in their transmission systems. The improved durability and performance led to enhanced vehicle reliability and customer satisfaction.

6.2 Aerospace Excellence

An aerospace company utilized DSP Precision Products’ stainless steel balls in their aircraft bearings. The balls’ exceptional performance under extreme conditions contributed to the safety and efficiency of their flight control systems.

6.3 Industrial Machinery Innovation

A major industrial machinery provider integrated DSP Precision Products’ alloy steel balls into their heavy-duty equipment. The balls’ high load-bearing capacity and resistance to wear improved the machinery’s performance and longevity.

7. Conclusion

DSP Precision Products Pvt. Ltd. epitomizes excellence in steel ball manufacturing, with over 30 years of experience and a commitment to quality and innovation. Their diverse range of steel balls serves a wide array of industries, from automotive and aerospace to industrial machinery and consumer goods. Their global reach and dedication to customer satisfaction underscore their position as a leader in the industry.

As DSP Precision Products continues to advance and adapt to the evolving needs of the market, they remain a benchmark for precision and reliability in steel ball manufacturing. Whether you are seeking high-quality components for industrial applications or looking for a trusted global supplier, DSP Precision Products Pvt. Ltd. is poised to deliver excellence and innovation.

Author’s Note: For more detailed information about DSP Precision Products Pvt. Ltd., their products, and global operations, please visit their official website or contact their sales team directly.

India’s No.1 Steel Balls Manufacturer by DSP Precision Products Pvt. Ltd.