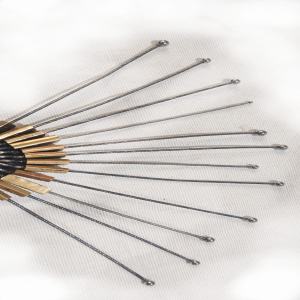

Wire Gauge Balls

Wire Gauge Balls by DSP Precision Products Pvt. Ltd.

Introduction

Wire gauge balls are precision-engineered components used in various industrial applications, including measuring and calibration tools, and as functional elements in machinery and equipment. DSP Precision Products Pvt. Ltd., with over 25 years of expertise, stands out as a leading manufacturer of these high-quality wire gauge balls. This article provides an in-depth exploration of DSP Precision Products Pvt. Ltd., detailing their manufacturing process, quality standards, product range, and global reach.

About DSP Precision Products Pvt. Ltd.

Founded over two decades ago, DSP Precision Products Pvt. Ltd. has carved a niche in the manufacturing sector by specializing in high-precision wire gauge balls. The company’s extensive experience and commitment to excellence have made it a trusted name in the industry. With a focus on premium quality and customer satisfaction, DSP Precision Products Pvt. Ltd. has established a strong global presence.

Experience and Expertise

With more than 25 years in the industry, DSP Precision Products Pvt. Ltd. has developed a profound understanding of the complexities involved in wire gauge ball manufacturing. This extensive experience enables the company to produce components that meet exacting standards of precision and performance.

- Technical Expertise: DSP Precision Products Pvt. Ltd. is adept at producing wire gauge balls with exact specifications. Their technical expertise spans a range of applications, from precise measurement tools to functional components in various mechanical systems.

- Innovative Manufacturing: The company has continually embraced technological advancements and innovative manufacturing techniques. This includes the use of advanced CNC machinery and sophisticated quality control measures to ensure the highest standards of product quality.

Manufacturing Process Wire Gauge Ball

The manufacturing process for wire gauge balls at DSP Precision Products Pvt. Ltd. is designed to achieve precision, consistency, and quality. Here’s a detailed look at the steps involved:

- Material Selection: High-quality raw materials are selected based on the specific requirements of the wire gauge balls. The choice of material affects the ball’s durability, strength, and performance.

- Common Materials: Stainless steel, brass, and carbon steel are commonly used for wire gauge balls due to their excellent mechanical properties and resistance to wear and corrosion.

- Machining: Advanced CNC (Computer Numerical Control) machines are utilized to shape the raw materials into wire gauge balls. This process involves precise turning, milling, and grinding operations to ensure the balls meet exact specifications.

- Precision Tolerances: The machining process is conducted with strict tolerances to ensure that each wire gauge ball is uniformly spherical and meets the required dimensions.

- Heat Treatment: To enhance the mechanical properties of the wire gauge balls, they undergo heat treatment. This involves heating the balls to a specific temperature and then cooling them in a controlled environment to achieve the desired hardness and strength.

- Heat Treatment Methods: Techniques such as annealing or quenching may be employed depending on the material and the intended use of the wire gauge balls.

- Polishing and Finishing: After machining and heat treatment, the balls are polished to achieve a smooth, high-quality surface finish. This step is crucial for applications requiring a high degree of precision and aesthetic quality.

- Surface Finishes: The surface finish can range from matte to highly polished, depending on the application and customer requirements.

- Quality Control: Rigorous quality control procedures are implemented throughout the manufacturing process to ensure that each wire gauge ball meets the highest standards. This includes dimensional inspections, surface finish evaluations, and performance tests.

- Inspection Techniques of Wire Gauge Balls : Techniques such as micrometer measurements, visual inspections, and hardness testing are used to ensure compliance with quality standards.

Commitment to Quality

DSP Precision Products Pvt. Ltd. is dedicated to maintaining high quality in all aspects of its wire gauge ball production. This commitment is demonstrated through their adherence to international quality standards and certifications.

- ISO Certification: The company is ISO 9001:2015 certified, which underscores its dedication to quality management. This certification indicates that DSP Precision Products Pvt. Ltd. consistently meets customer requirements and adheres to regulatory standards.

- Quality Management System: The ISO certification encompasses all aspects of the manufacturing process, from material selection to final product delivery, ensuring comprehensive quality management.

- Customer Satisfaction: DSP Precision Products Pvt. Ltd. places a high priority on customer satisfaction. The company’s customer-centric approach includes providing detailed product specifications, ensuring timely deliveries, and offering responsive customer support.

- Customization Options: The company offers customization for wire gauge balls to meet specific customer needs, including variations in size, material, and surface finish.

Size Chart and Specifications of Wire Gauge Balls

DSP Precision Products Pvt. Ltd. manufactures wire gauge balls in a wide range of sizes to cater to various industrial requirements. The company can produce balls of different diameters and tolerances to meet specific application needs.

- Size Range: Wire gauge balls are available in a broad range of sizes, typically from 1 mm to 50 mm in diameter. Custom sizes can also be produced based on individual customer requirements.

- Standard Sizes: Commonly available sizes include 2 mm, 5 mm, 10 mm, 15 mm, 20 mm, and 25 mm. DSP Precision Products Pvt. Ltd. can accommodate custom orders for sizes outside this range.

- Dimensional Tolerances: The company adheres to precise dimensional tolerances to ensure consistency and accuracy. Tolerances are specified according to industry standards or customer specifications.

- Typical Tolerances: Tolerances generally range from ±0.01 mm to ±0.1 mm, depending on the size and application of the wire gauge balls.

Chemical Composition

The chemical composition of wire gauge balls plays a crucial role in determining their mechanical properties and suitability for different applications. DSP Precision Products Pvt. Ltd. uses a variety of materials, each with specific chemical compositions.

- Stainless Steel (e.g., 304 or 316):

- Iron (Fe): Balance

- Chromium (Cr): 18-20%

- Nickel (Ni): 8-10%

- Carbon (C): ≤0.08%

- Properties: Known for its excellent corrosion resistance, strength, and durability. Suitable for applications requiring high resistance to environmental factors.

- Brass (e.g., C26000 or C36000):

- Copper (Cu): 60-70%

- Zinc (Zn): 30-40%

- Lead (Pb) (for free-cutting brass): Up to 2%

- Properties: Offers good machinability and corrosion resistance. Suitable for applications where ease of machining and moderate strength are required.

- Carbon Steel (e.g., AISI 1045):

- Iron (Fe): Balance

- Carbon (C): 0.43-0.50%

- Manganese (Mn): 0.60-0.90%

- Properties: Provides high strength and hardness. Often used in applications requiring robust performance and resistance to wear.

Applications

Wire gauge balls manufactured by DSP Precision Products Pvt. Ltd. are used in a variety of industries and applications. Their precision and quality make them suitable for several critical functions.

- Measurement and Calibration: Wire gauge balls are used in precision measurement tools and calibration devices. Their uniformity and accuracy are essential for ensuring reliable measurements and calibrations.

- Mechanical Components: In mechanical assemblies, wire gauge balls serve as key components in bearings, valves, and other mechanisms where precise sizing and smooth operation are required.

- Aesthetic and Decorative Uses: Wire gauge balls are also employed in decorative applications where their appearance and quality contribute to the overall design.

Global Reach and Export

DSP Precision Products Pvt. Ltd. has a well-established global presence, exporting wire gauge balls to various international markets. The company’s success in the global market is a testament to its high-quality products and reliable service.

- Export Markets: The company serves a diverse range of markets across North America, Europe, Asia, and Africa. This international reach demonstrates the widespread acceptance of DSP Precision Products Pvt. Ltd.’s wire gauge balls in different industrial sectors.

- Logistics and Distribution: Efficient logistics and distribution systems ensure that products are delivered to international customers in a timely manner. DSP Precision Products Pvt. Ltd.’s experience in handling global trade regulations and shipping logistics contributes to its successful export operations.

Conclusion

DSP Precision Products Pvt. Ltd. stands out as a leading manufacturer of wire gauge balls with over 25 years of industry experience. The company’s commitment to quality, innovation, and customer satisfaction is reflected in its comprehensive manufacturing process, adherence to international standards, and global market presence. By offering a wide range of sizes, precise dimensional tolerances, and various materials, DSP Precision Products Pvt. Ltd. meets the diverse needs of its customers. Their dedication to producing high-quality wire gauge balls and providing exceptional service makes them a trusted choice for industries worldwide.