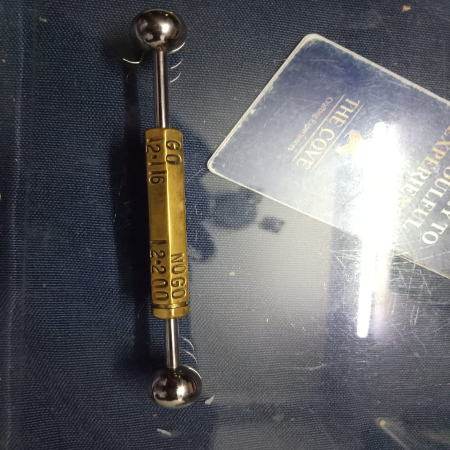

Brass Handle Gauge

Brass Handle Gauges by DSP Precision Products Pvt. Ltd.

Introduction

Brass handle gauges are critical precision tools used for measuring and inspecting handle components in various industries. DSP Precision Products Pvt. Ltd., a distinguished manufacturer with over 25 years of experience, specializes in producing high-quality brass handle gauges. These gauges are meticulously engineered to meet specific customer requirements and are exported worldwide. This comprehensive description explores the features, manufacturing process, customization options, and global reach of the brass handle gauges produced by DSP Precision Products Pvt. Ltd.

1. Company Overview

1.1. History and Expertise

Founded over 25 years ago, DSP Precision Products Pvt. Ltd. has built a reputation as a leader in precision engineering. The company has extensive experience in manufacturing high-quality precision tools, including brass handle gauges. DSP Precision Products Pvt. Ltd. combines technological innovation with skilled craftsmanship to deliver products that meet the highest standards of accuracy and reliability.

1.2. Global Export Capabilities

With a robust global export network, DSP Precision Products Pvt. Ltd. serves clients across multiple continents. The company’s adherence to international quality standards and commitment to delivering consistent, high-quality products have established it as a trusted supplier worldwide. Efficient logistics and dedicated customer support further enhance the company’s ability to meet international demands.

2. Brass Handle Gauge Specifications

2.1. Purpose and Function

Brass handle gauges are precision instruments used to measure and verify the dimensions of handle components. These gauges ensure that handles meet specified tolerances and quality standards, making them essential in industries where precision and consistency are crucial.

2.2. Design and Materials

- Materials: Brass handle gauges are manufactured from high-quality brass, known for its excellent machinability, durability, and resistance to corrosion. Brass offers a good balance of strength and workability, making it ideal for precision measurement tools.

- Design: The design of brass handle gauges involves precision machining to achieve the exact dimensions and features required for accurate measurement. The gauges are engineered to provide reliable performance and ensure that handle components meet the required specifications.

2.3. Accuracy and Tolerance

- Precision: Brass handle gauges are designed to provide high precision in measurements, often within micrometric tolerances. This ensures that the gauges can accurately assess whether handle components conform to their specified requirements.

- Calibration: Regular calibration is essential to maintain the accuracy of brass handle gauges. DSP Precision Products Pvt. Ltd. employs rigorous calibration procedures to ensure that all gauges meet industry standards and deliver consistent performance.

3. Manufacturing Process

3.1. Raw Material Selection

The manufacturing process begins with the selection of high-quality brass. The brass is carefully inspected to ensure it meets the required standards for purity and composition. This ensures that the final product will have the desired mechanical properties and performance characteristics.

3.2. Machining and Shaping

- Turning and Milling: Brass is subjected to turning and milling processes to achieve the basic shape and dimensions of the handle gauges. Precision machines are used to ensure that the dimensions are accurate and consistent.

- Drilling and Reaming: Additional machining operations, such as drilling and reaming, are performed to create precise holes and internal features required for the gauges.

3.3. Finishing and Polishing

- Grinding: After the initial machining, the gauges undergo grinding to achieve precise dimensions and a smooth surface finish. This step is crucial for ensuring that the gauges meet stringent tolerance requirements.

- Polishing: The gauges are polished to achieve a high-quality surface finish. Polishing enhances the appearance of the gauges and reduces surface imperfections.

3.4. Calibration and Quality Control

- Calibration: Each brass handle gauge is calibrated to ensure it meets the required specifications. Calibration involves comparing the gauge against known standards and making any necessary adjustments.

- Quality Control: Rigorous quality control measures are implemented throughout the manufacturing process to ensure that each gauge meets high standards. This includes dimensional inspection, functional testing, and material testing.

4. Customization and Flexibility

4.1. Custom Sizes and Specifications

DSP Precision Products Pvt. Ltd. offers extensive customization options for brass handle gauges. Clients can specify various sizes, tolerances, and designs to meet their specific requirements. The company’s flexibility allows for the production of gauges tailored to unique applications and industry standards.

4.2. Custom Finishes and Coatings

Customers can request brass handle gauges with custom finishes or coatings. For example, gauges may be coated with anti-corrosive materials or treated to achieve specific colors or surface textures. Custom finishes enhance the functionality and appearance of the gauges.

4.3. Technical Support

The company’s experienced technical team provides expert guidance to clients, assisting with material selection, design considerations, and customization options. This support ensures that clients receive handle gauges tailored to their precise needs and applications.

5. Applications

5.1. Manufacturing and Quality Control

- Handle Components: Brass handle gauges are used to measure and inspect handle components in various manufacturing processes. They ensure that handles meet specified tolerances and quality standards.

- Assembly Lines: In assembly lines, handle gauges are employed to verify the dimensions of handles before they are assembled into final products. This helps ensure consistent quality and performance.

5.2. Automotive Industry

- Interior Components: Brass handle gauges are used to inspect and measure interior components of vehicles, such as door handles and control knobs. Their precision ensures that these components meet required specifications for fit and function.

- Exterior Parts: The gauges are also used to inspect exterior handles and other components, ensuring that they meet quality standards and perform reliably in automotive applications.

5.3. Aerospace Industry

- Aircraft Handles: In the aerospace industry, brass handle gauges are used to inspect handles and control mechanisms in aircraft. Their accuracy ensures that these critical components meet stringent safety and performance standards.

- Spacecraft Components: Brass handle gauges may also be used in spacecraft components, where precision and reliability are crucial.

5.4. Electronics Industry

- Control Panels: Brass handle gauges are used to measure and inspect control panels and switches in electronic devices. This ensures that these components meet precise dimensional requirements and function correctly.

- Enclosures: In electronics enclosures, handle gauges help ensure that handle fittings and other components meet specified tolerances and quality standards.

5.5. Medical Devices

- Instrument Handles: Brass handle gauges are used to inspect handles on medical instruments and devices. Their precision ensures that these components meet required specifications for functionality and safety.

- Equipment Calibration: The gauges are also used in the calibration of medical equipment, ensuring that handles and other components are accurately measured and adjusted.

5.6. Consumer Products

- Furniture: Brass handle gauges are used to inspect handles and fittings on furniture. Their accuracy ensures that these components meet design specifications and provide a high-quality user experience.

- Home Appliances: In home appliances, handle gauges are used to verify the dimensions and quality of handles, ensuring consistent performance and reliability.

6. Advantages of DSP Precision Products Pvt. Ltd.’s Brass Handle Gauges

6.1. Extensive Expertise

With over 25 years of experience, DSP Precision Products Pvt. Ltd. has developed a deep understanding of handle gauge manufacturing. This expertise ensures that each gauge is produced to the highest standards of accuracy and reliability.

6.2. Premium Quality Assurance

The company’s commitment to using high-quality materials and implementing rigorous quality control measures guarantees that each brass handle gauge meets stringent industry standards. This focus on quality ensures consistent performance and durability.

6.3. Customization Capabilities

DSP Precision Products Pvt. Ltd. offers extensive customization options for brass handle gauges, allowing clients to obtain products tailored to their specific needs. This flexibility enhances the utility and performance of the gauges in various applications.

6.4. Global Export Reach

The company’s global export capabilities enable it to serve a wide range of international clients. DSP Precision Products Pvt. Ltd.’s reputation for quality and reliability has established it as a preferred supplier in global markets.

7. Environmental Considerations

7.1. Sustainable Practices

DSP Precision Products Pvt. Ltd. is committed to sustainability and minimizing the environmental impact of its manufacturing processes. The company implements energy-efficient practices and strives to reduce waste throughout its operations.

7.2. Recycling and Waste Management

The company’s recycling and waste management practices contribute to resource conservation and environmental sustainability. Scrap material from production is collected and recycled to reduce environmental impact.

8. Conclusion

DSP Precision Products Pvt. Ltd.’s brass handle gauges exemplify the company’s dedication to precision engineering, premium quality, and customer satisfaction. With over 25 years of experience and a strong global presence, the company has established itself as a leader in the manufacturing of high-quality brass handle gauges.

The combination of extensive industry expertise, advanced manufacturing processes, rigorous quality control, and extensive customization capabilities ensures that each brass handle gauge meets the highest standards of performance and reliability. Whether for manufacturing, automotive, aerospace, electronics, medical devices, or consumer products, DSP Precision Products Pvt. Ltd. continues to deliver products that enhance quality control and meet the demands of modern engineering.